Together we innovate

The EIC (Energy Innovation Centre) brings industry and innovators together. As a not-for-profit organisation, we operate a shared platform and provide an open environment for our partners and community, in the energy and utilities industries, to innovate together. Improving the quality of people’s lives is at the core of what we do, and by working together we can achieve a safe, affordable, net-zero future for everyone.

£50M

Investments secured for the innovation community to date

200+

Managing over 200 calls for innovation

10,000+

Working with 10,000+ innovators

What is the EIC?

The EIC is a not-for-profit energy organisation that supports innovators to find new project opportunities in gas and electricity transmission and distribution.

In partnership with seven of the UK’s energy networks coming together, we’re striving to bring innovation forward as the world transitions to low-carbon economy.

Electricity Distribution Partners

Gas Distribution Partners

Electricity Transmission Partners

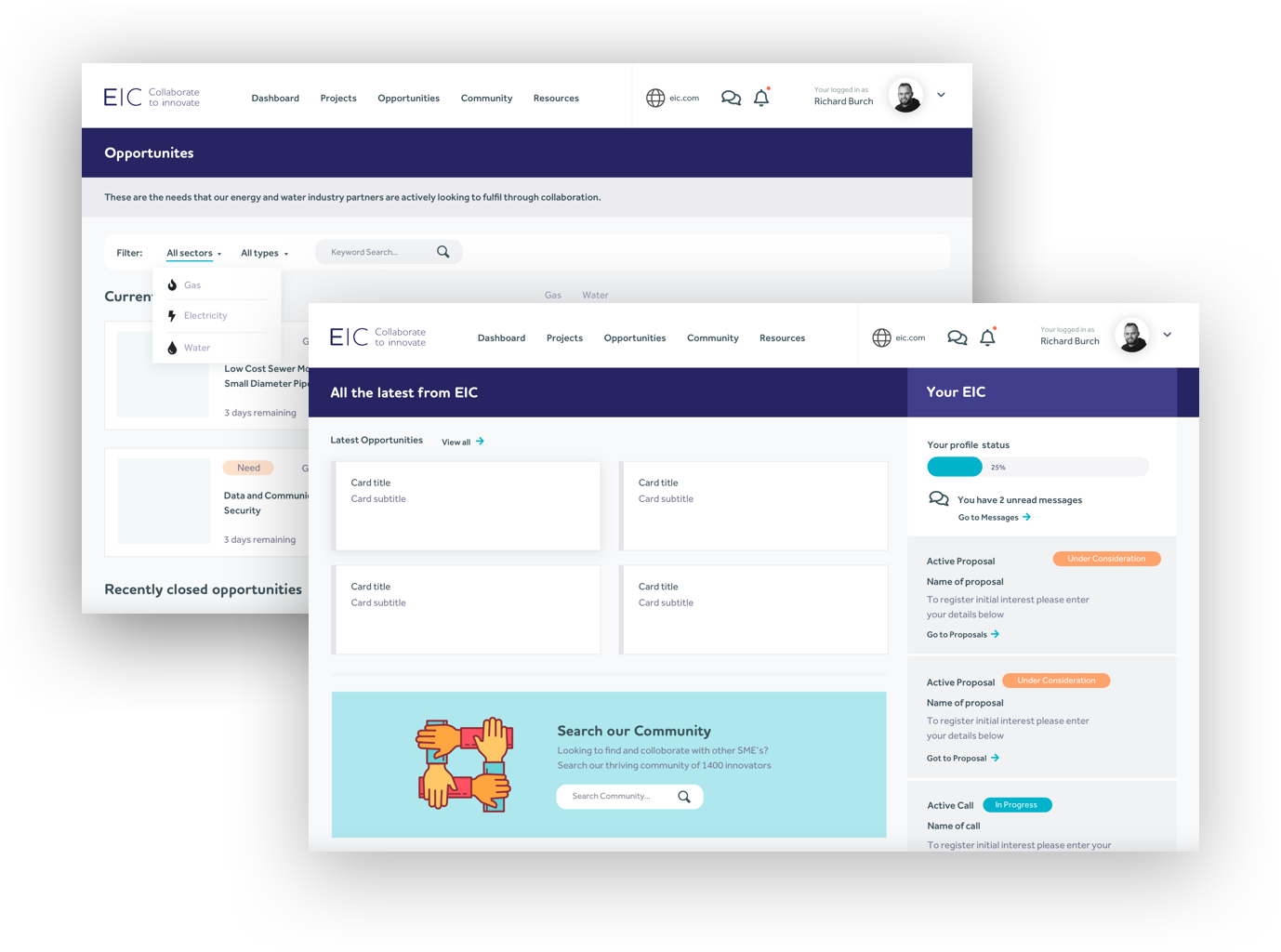

Engage with us

Through innovation, together we can deliver a decarbonised future and achieve net zero targets. Our platform highlights the areas our partners are seeking solutions for, offering innovators a place to propose their ideas.

Opportunities

View the areas our partners are seeking innovative solutions to solve industry problems.

What we've achieved

See real-life projects where the EIC have facilitated innovation.

Access to the latest opportunities in the industry

Funding support and guidance

Connect and collaborate with innovators in the industry

Sign up to our energy innovation hub to take advantage of the benefits and see our innovation opportunities

What innovators think

The EIC has opened the doors for us... We couldn’t have done it without them. My advice to Innovators starting out is to go through the EIC.

My experience with the EIC has been very good. They managed all our finances, monthly reports and helped us bring the project into fruition.

Working with the EIC has been great!...They are essentially a big brother to help you if you feel overwhelmed with the size of a project, they are always very helpful.